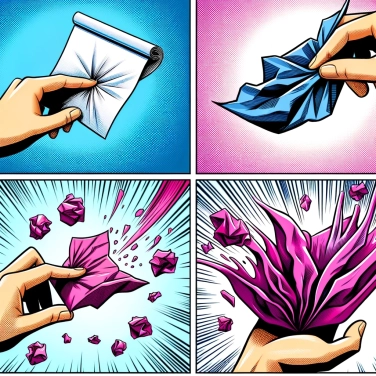

When paper is wrinkled, the fibers become disorganized and break, making it fragile. By ironing it hot, the fibers realign and set again, strengthening its structure and making it more resistant.

When you crumple paper, the cellulose fibers it contains get tangled and disorganized. When you then smooth this paper with heat, these heated fibers regain a more regular order: this is called molecular reorganization. Under the effect of heat, the cellulose molecules gain mobility and arrange themselves better with each other. As a result, their structure becomes denser, more stable, and therefore stronger. It's a bit like carefully putting a complete mess back in a closet; it fits better, stabilizes better, and ultimately holds together much better.

Heat directly affects the hydrogen bonds present in the cellulose fibers of paper. When these fibers are heated, they absorb energy, allowing the internal hydrogen bonds to partially and temporarily break. As a result, the cellulose molecules can move more freely to reorganize optimally. Upon cooling, new connections are formed, often more numerous and better distributed. These new hydrogen bonds then make the paper stronger and more mechanically resistant. It is a kind of molecular reset, where the fibers have a second chance to better cling to each other.

When you heat and smooth your crumpled paper, you force the cellulose fibers to come closer together and reorganize better. With the heat, the hydrogen bonds between these fibers, which were previously a bit chaotic, become significantly more efficient and regular. The result: you achieve reinforced contact areas, where the previously crumpled fibers now fit together more solidly. This new proximity of the molecules allows for a more harmonious distribution of mechanical stress throughout the paper. It is this meticulous and organized closeness that makes your heated, then smoothed paper stronger than when it was simply crumpled.

When paper is crumpled and then smoothed while hot, its cellulose fibers undergo a structural realignment. Initially, they are disordered and dispersed, but after heating, they align better and establish new bonds with each other. These enhanced molecular interactions provide the paper with improved strength and better mechanical resistance. The now more coherent structure allows it to better withstand mechanical stress without tearing or stretching too easily. In short, the paper, after this treatment, performs better under stress due to this new internal organization of its fibers.

The industrial process called calendering uses heat and pressure to smooth and strengthen paper, a mechanism similar to that used to flatten crumpled paper at home.

Cellulose fibers, when lightly heated and compressed, can generate an additional 10 to 15% in mechanical strength compared to their initial state.

Internal hydrogen bonds, essential for the strength of paper, are also responsible for the stable three-dimensional structure of water in its ice form.

In the 1940s, by experimenting with the properties of wood and paper, scientists paved the way for the development of new methods to strengthen cellulose-based materials, thereby contributing to various technological advancements.

In general, yes. Recycled paper undergoes repeated processing that shortens and somewhat weakens the cellulose fibers over the cycles. This degradation affects its ability to recover after being crumpled, even when a heating and smoothing operation is used.

Ironing with a hot iron temporarily improves the internal organization of the fibers and recreates internal hydrogen bonds that were broken by wrinkling. This reorganization thus strengthens the internal cohesion of the fibers, increasing the overall mechanical strength of the paper.

Yes. Excessive heating can damage the cellulose structure of paper, cause yellowing, or lead to increased brittleness of the material. Therefore, it is better to apply moderate and controlled heat to achieve the best results while preserving the initial properties of the paper.

Yes. Thick papers rich in long plant fibers respond better to heating and smoothing, as they have more numerous and robust internal hydrogen bonds. Thin papers or those that are heavily chemically treated tend to benefit less clearly from this process in terms of mechanical reinforcement.

No, a heavily crumpled paper does not usually fully regain its original properties. However, hot smoothing allows for a partial reorganization of the cellulose fibers, significantly improving its mechanical strength compared to its initial crumpled state.

No one has answered this quiz yet, be the first!' :-)

Question 1/5